Activities sectors

At the service of industry

Our specialisations have enabled us to support manufacturers in the food, water treatment, chemical and heavy industry sectors in their investment projects for over 15 years, taking into account the specific requirements of each. “Towards a greener, more efficient industry, serving consumers and the planet”.

Chemicals and Petrochemicals

Chemicals and Petrochemicals

Assistance to contracting authorities, project management

Technical specifications, tender specifications, planning and cost-control, project managers, subcontractor monitoring, preparation of work files, site supervision, drafting of test procedures, test management, health, safety, environment, etc.

Document engineering, EDM (Electronic Document Management)

Digitisation, processing of data and measurements, drafting and updating of ranges, operating rules, management of spare parts, history of interventions.

Technical engineering, studies

Mechanical engineering, piping, process engineering, general installation, boiler making, rotating machinery, electricity, automation, instrumentation, fire protection, hydraulics, special machinery, calculation notes, metal structures, scientific and technical computing.

Project References

Chemical plant in Feuchy

Automation of a warehouse

Fertiliser plant

Chemical plant in Feuchy

Objectives

Technical assistance in the design office for various projects over a period of 4 years in the plant

Activities carried out by the RNI employee

3D / 2D CAD design

Animation of layout reviews and 3D models

Dimensioning and production of isometrics

Drawing up specifications

Invitation to tender and technical comparison

Contacting suppliers and service providers

Site supervision

Tools / Methodologies AUTOCAD

AUTOCAD PLANT

NAVISWORK

RECAP

Plant

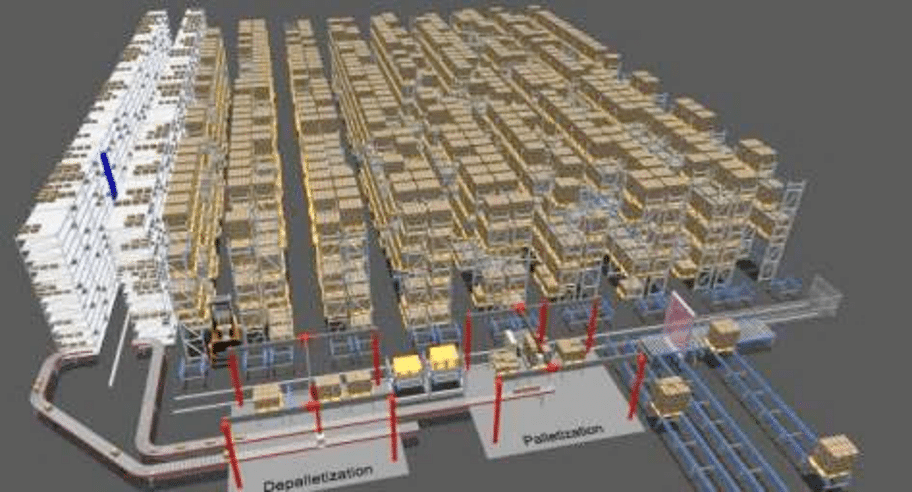

Automation of a warehouse

Objectives

C210 shop automation

Budget

4.5M + €1M

Key figures

Heterogeneous palletising: 5 cartons/min, 4,200 cartons/day palletised + 800 references

3,000 pallets stored + 14,000 cartons in the miniload

2 VNA, 1 palletising robot, 1 depalletising robot, 1 stacker crane, 1 shuttle

3,000m2 of storage + 600m2 of “robot” area

RNI achievements

Project management assistance (1 project manager + 1 project officer)

Drafting of specifications

Technical comparisons

Running meetings (weekly, monthly, site meetings, etc.)

Budget and schedule implementation/monitoring

FAT/SAT

Coordination of design and site work

Follow-up of commissioning

CE certification

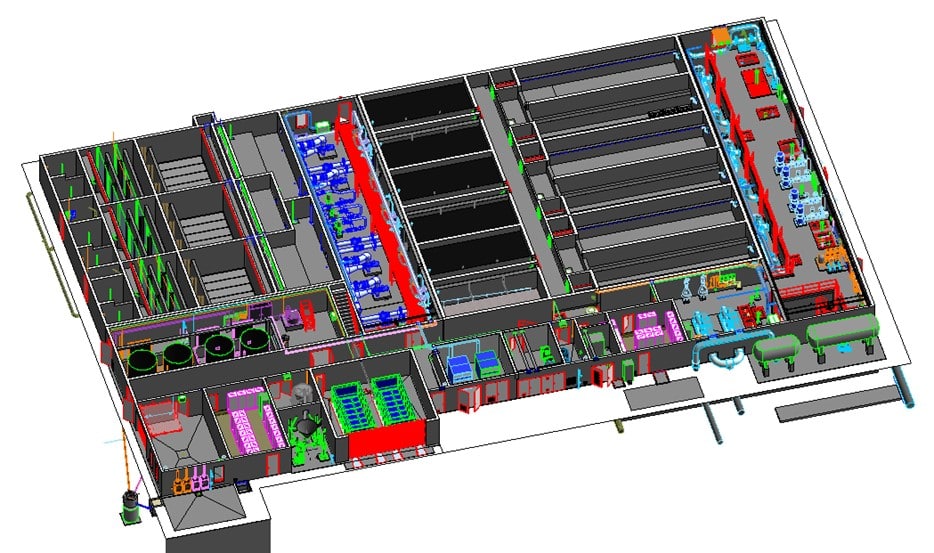

3D of the project

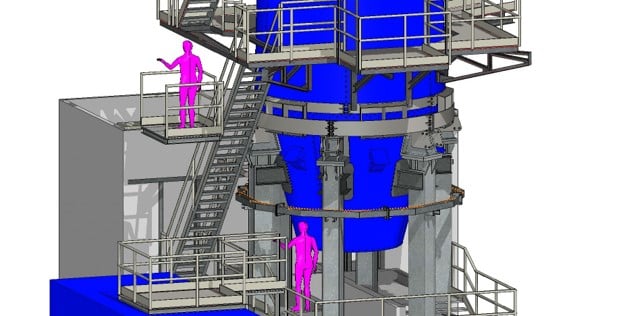

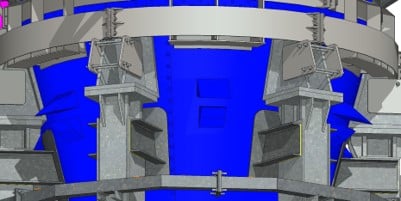

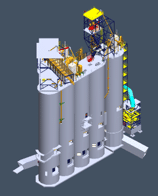

Fertiliser plant

Objectives

RNI supported ROSIER / BOREALIS S.A. in the revamping of its G1 workshop located in Franes-Les-Anvaing (Belgium) and the replacement of its granulator

Activities carried out by the RNI employee

CAD design

Improvement of process networks

Collecting and checking engineers’ calculation notes

Proposing and implementing work methodologies

Drawing up specifications

Project management

Leading meetings

Site supervision

Team coordination

Prioritising day-to-day tasks

Assistance with return to service

Tools / Methodologies AUTOCAD

AUTOCAD PLANT

NAVISWORK

RECAP

Food-processing-industry

Food-processing-industry

Project Management

Technical specifications, tender specifications, planning and cost-control, project managers, subcontractor monitoring, preparation of work files, site supervision, drafting test procedures, conducting tests, health, safety, environment

Technical engineering, studies

Mechanics, piping, process engineering, general installation, boiler making, rotating machinery, electricity, automation, instrumentation, fire protection, hydraulics, special machinery, calculation notes, metal structures, scientific and technical computing, automation, LV/HV electricity and instrumentation

Process Engineering

Material balances, process diagrams, PID, unit operations, mechanics, creation of datasheets, equipment sizing: exchangers, tanks, etc.

Mass and energy balances, pressure loss calculations

Utilities: energy balances, fluid production and distribution

Project references

Installation of a filter press in a sugar factory

Installation of a production line

Installation of a filter press in a sugar factory

Objectives

Install a filter press, design the building

- Budget: €5.5m

Achievements

- Feasibility study and building layout

- Piping, 650m rack and connection to the existing system

- Drafting of invitations to tender by lot and by trade (GC, Structural work, Piping, Equipment, Ventilation, Overhead travelling crane, Control room, etc.)

- Drawing up comparative tables

- Budget management

- Site coordination

- Organising weekly meetings with the various people involved in the project

- Acceptance of work, tests, trials and commissioning with the operator

Tools

- Autocad

Installation of a production line

Project key figures

As part of a requirement to increase production capacity, our client was planning to install a new production line. RNI was consulted for the design and supervision of the works

- Budget 10 million euros

- Project team of 3 people

- Production start-up on schedule

- Max production 6T/h

Activities

- CAD design (Civil Works guide drawings, networks, infrastructure and machine placements)

- Field survey

- Project management

- Chairing meetings

- Site supervision

- Team coordination

Tools

- Autocad

Pharmacy

Pharmacy

Project Management

Technical specifications, tender specifications, planning and cost-control, project managers, subcontractor monitoring, preparation of work files, site supervision, drafting test procedures, conducting tests, health, safety, environment

Technical Engineering, studies

Mechanics, piping, process engineering, general installation, boiler making, rotating machinery, electricity, automation, instrumentation, fire protection, hydraulics, special machinery, calculation notes, metal structures, scientific and technical computing, automation, LV/HV electricity and instrumentation

Process Engineering

Material balances, process diagrams, PID, unit operations, mechanics, creation of datasheets, equipment sizing: exchangers, tanks, etc.

Mass and energy balances, pressure loss calculations

Utilities: energy balances, production and distribution of fluids

Water and environment

Water and environment

Project Management

Production of APS, APD, technical specifications, tender specifications

Design of new units or building extensions, renovation of existing installations

Technical Engineering, studies

Layout of equipment, modelling of workshops, production of guide drawings, HVAC and AHU networks, routing of cable trays, heat pumps, boilers, biogas network, piping, etc.

Definition and creation of the hydraulic profile of the installations

Project References

Chevigny Saint Sauveur water treatment plant (Dijon)

Valedeau treatment plant (Montpellier)

Extension of the Caen sludge methanisation plant

Chevigny Saint Sauveur water treatment plant (Dijon)

Objectives

The RNI design office was responsible for adding two extra tanks and new filtration equipment

Achievements

- Reassembly of the model with a period plan

- CAD design using PIDs

- Layout of the plant, Civil Work

Design tool

- Autocad REVIT

Valedeau treatment plant (Montpellier)

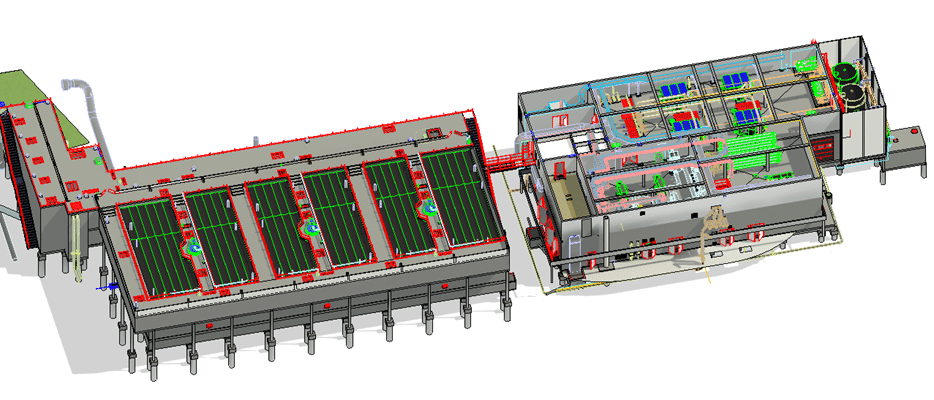

Objectives

Construction of a water treatment plant in Montpellier

- RNI carried out the entire study for the treatment building

Achievements

- Layout, modelling and production of guide drawings

- Drawing cable trays

- Drawing of pipework

Design Tool

- Autodesk Revit

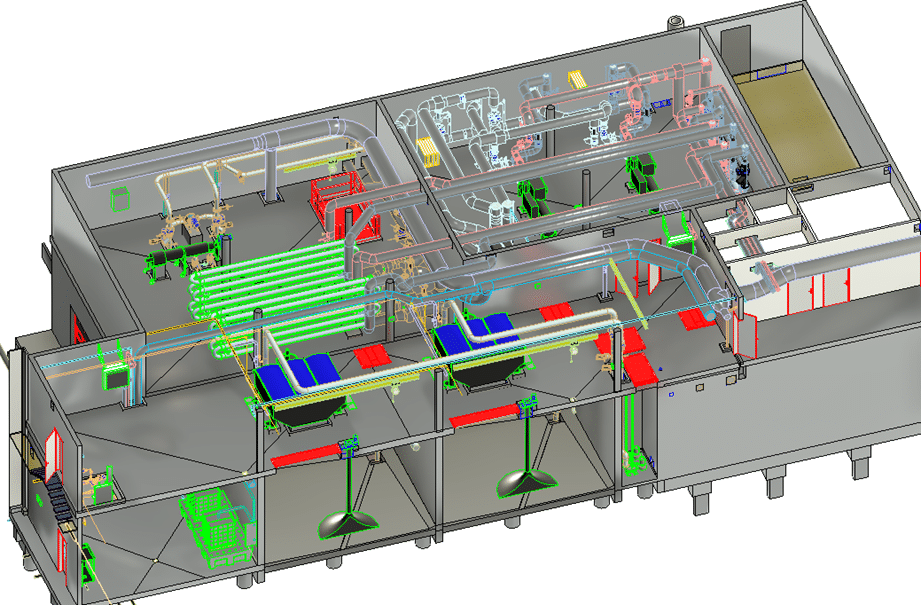

Extension of the Caen sludge methanisation plant

Objectives

- Extension of capacity and anaerobic digestion of sludge from the New World plant

- Study of the sludge building and distribution structure

Achievements

- Layout diagrams

- Equipment modelling

- Guide drawings

- HVAC and AHU drawings

- Cable trays

- Heat pumps and boilers

- Biogas network

- Piping

Design Tool

- Autodesk Revit

Energies

Energies

Technical engineering, Preliminary Design

Audits, feasibility studies, general project organisation, equipment specification, APS/APD studies

Mechanical engineering, hydraulics, calculation notes

Quality, Regulations

Drafting of regulatory dossiers in application of codes and standards (ASME, RCCM, ESPN), quality of design and manufacturing processes

Electrical Engineering

Electrical engineering, sizing of electrical installations (LV/HV), instrumentation and regulation, control and command

Project Management

Technical specifications, site supervision, test management, project management

Engineering

Engineering

Project management

Technical specifications, tender specifications, planning and cost-control, project managers, subcontractor monitoring, preparation of work files, site supervision, drafting test procedures, conducting tests, health, safety and the environment

Technical Engineering, Studies

Mechanical engineering, piping, process engineering, general installation, boiler making, rotating machines, electricity, automation, instrumentation, fire protection, hydraulics, special machines, calculation notes, metal structures, scientific and technical computing, automation, LV/HV electricity and instrumentation

Process Engineering

Material balances, process diagrams, PID, unit operations, mechanics, creation of datasheets, equipment sizing: exchangers, tanks, etc.

Mass and energy balances, pressure loss calculations

Utilities: energy balances, fluid production and distribution

Project References

Study of the networks of a cement plant in Canada

Study of the networks of a cement plant in Canada

Objectives

We are working with our client on the design of a cement plant in Canada

Achievements

- Checking 2D plans

- Checking 3Ds against 2D plans

- Reassembly of 3D in the general model

- Creation of routings and 3D supports

- Detection of clashes in the model

- Writing comments and photo reports

- Coordination meetings between the various organisations involved in the project

Tools

Solidworks

Metallurgy and Steel Industry

Metallurgy and Steel Industry

Project Management

Drawing up APS, APD, technical specifications, tender specifications, planning and cost-control, project managers, monitoring subcontracting studies, preparing work files, site supervision, drafting test procedures, conducting tests, health, safety and the environment

Technical engineering, Studies

Mechanical engineering, piping, process engineering, general installation, boiler making, rotating machinery, electricity, automation, instrumentation, fire protection, hydraulics, special machinery, calculation notes, metal structures

Investment Management

Purchasing, management control, budget and resource management

Sectors

Coking plant, Cast iron, Steelworks, Hot and cold rolling, Cross-plant projects (Reliability, Maintenance), Industrial IT, Maintenance

Manufacturing Industry

Manufacturing Industry

Pre Project Studies

Audits, feasibility studies, general project organisation, equipment specification, carrying out APS/APD studies

Technical Engineering, Studies

Mechanical engineering, hydraulics, calculations, piping and general installation

Electrotechnics

Electrical engineering, sizing of electrical installations (LV/HV), instrumentation and control, automation

Project Management

Technical specifications, site supervision, test management, project management, industrialisation methods

Project References

Network studies for a cement plant

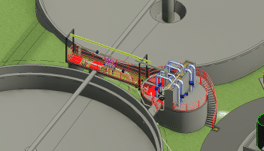

Network studies for a cement plant

Objectives

The RNI design office is responsible for designing the various networks throughout a cement plant

Achievements

- Drawing up PID diagrams

- Flow calculations to define pipe diameters

- CAD design of all networks

- Creation of rooting isometries

- Design of support specifications for all workshops

- Design of the various racks between the workshops, including calculation notes

- Rack manufacturing plan

- Quantification of all equipment used for all studies

Tools

- REVIT

- AutoCAD

- Microstation AECOsim

Contact