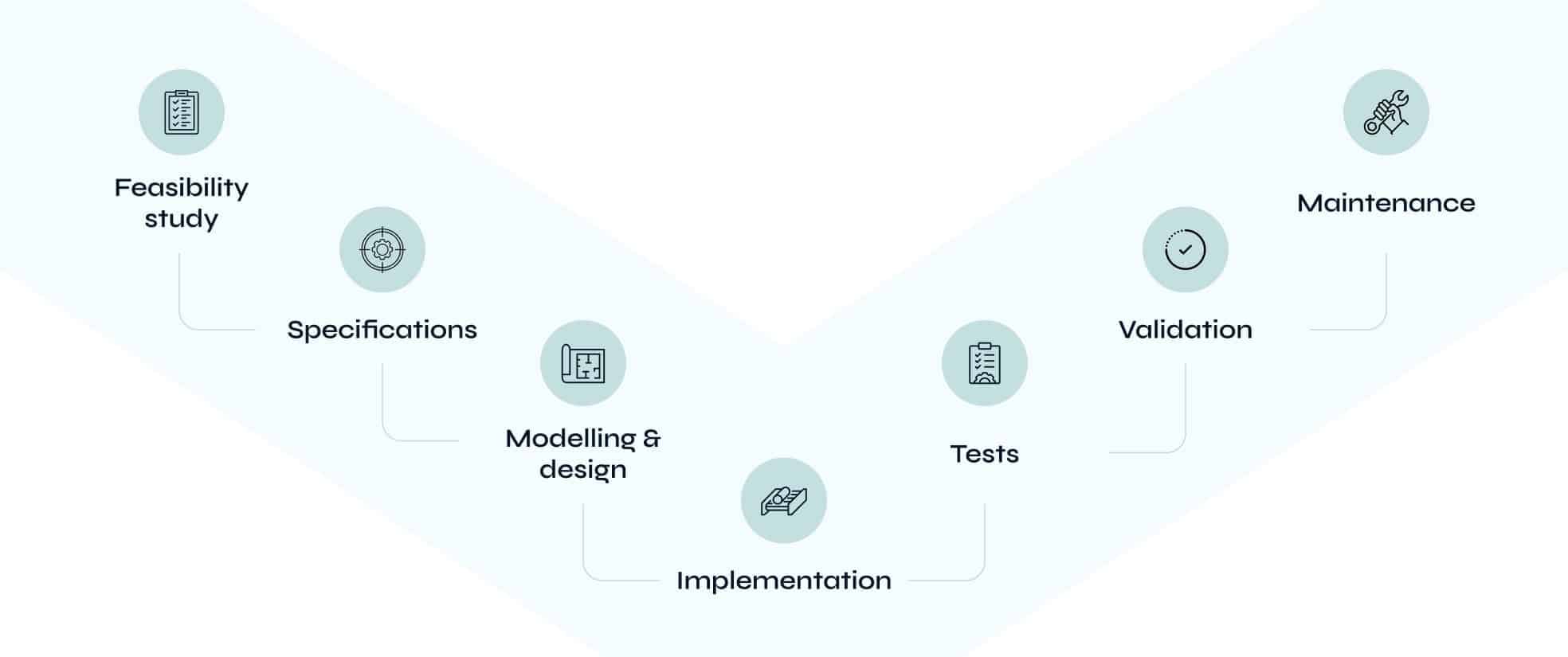

Our expertise extends to all the design phases of the V cycle

Our activities

- Boiler making

- Water treatment

- Piping

- Process

- Mechanics

- Steel framework

- Calculation of parts and assemblies

Boiler making

- Drawings of assemblies and manufacturing details in accordance with CODAP and ASME standards

- Production of parts lists

- On-site surveys

Water treatment

- Production of PIDs, Hydraulic Profiles and Synoptics

- Design and production of assembly drawings

- Design and production of plans Civil engineering guide

- Creating isometries and parts lists

- Drawing up support plans

- Production of TQC plans

- On-site monitoring and surveys

Piping

- Drawing up layout plans

- Design and production of overall drawings and installation details

- Production of PID diagrams

- Making isometries

- Drawing up support plans

- On-site surveys + site monitoring and organisation

- Drafting of specifications

- Production and management of consultation files

- Creating schedules

- Production of TQC plans

Process

- Process / Utility sizing

- Process balances (mass / energy)

- Technical specifications

- PID

- Functional analysis

- Equipment pre-sizing

- Budget estimate

Mechanics

- Drawing up specifications

- Design and production of assembly drawings and manufacturing details

- Creation of nomenclatures

- Special machines design

- Tooling design

- Packaging lines

- Creation and management of technical files

Steel framework

- Drawing up calculation notes:

– We carry out calculations in accordance with the Eurocodes in order to guarantee validation by the inspection bodies.

– We use tools that can be adapted to any BIM process, enabling your project to be integrated into OPEN BIM workflows. - This means you can communicate quickly and efficiently with the other parties involved in your project.

- Types of calculations :

– Structures, staircases, railings or any steel structure (EUROCODE 3)

– Aluminium structures (EUROCODE 9)

– Timber structures (EUROCODE 5)

– Interior or exterior structures

– Structures in seismic zones

– Non-linear analysis

– Eigenmode analysis - Design and production of assembly drawings

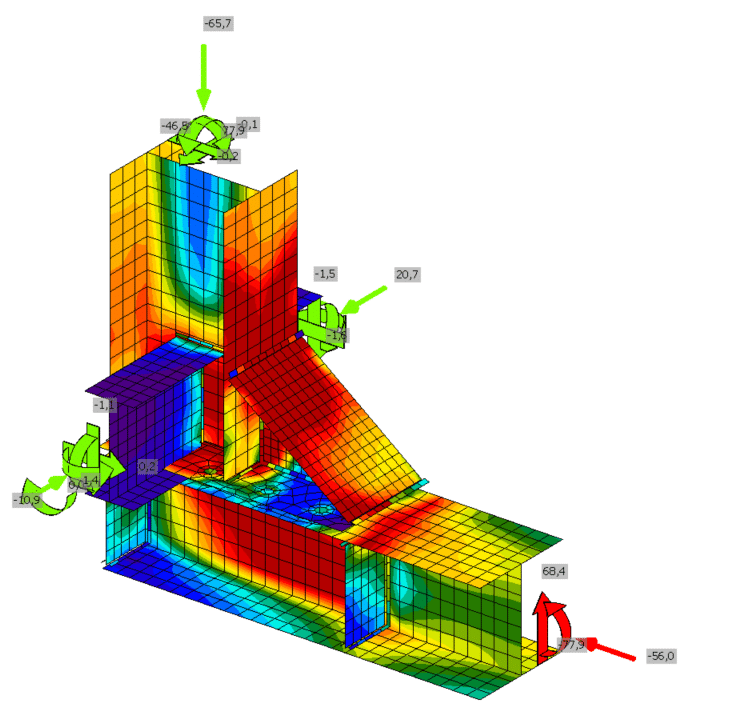

Calculation of parts and assemblies

- RNI carries out finite element calculations to study the mechanical behaviour of your static or dynamic parts and assemblies: elastic studies, vibration analysis.

- Our experienced team will help you draw up your specifications and assist you in designing a product that is perfectly suited to its use and your needs:

Sizing - We work with you right from the design phase. This ensures that you are in control of your project, so that your product quickly meets the mechanical specifications. A preliminary study can be carried out for your costing needs.

- Validation

– A note can be drawn up to ensure that your product is suitable for normal use, thereby reducing your costs in real-life testing. - Optimisation

– Cost or weight reduction, design optimisation

- Our equipment

- At our customers

- Our licences

-

A colour plotter and a cutting machine for plans up to A0

Scan 3D

Fully equipped meeting room

2 NAS for backup, one local, the other external

10 top-of-the-range 3D CAD workstations (2×27″ screens, Nvidia Quadro graphics card, SSD disk)

A local computer server

-

20 computers (office automation, CAD, laptops)

-

Autocad 2D /3D

Autocad plant

Tekla

Revit

Ansys

Solidworks

AecoSim

Autocad Plant 3D